Amey Sogodekar.

Wheel Assembly Design of a FSAE car

In collaboration with

Role

Design Engineer

Type

Individual

Duration

January 2019 - June 2019

Brief

Acceleracers is the official FSAE team of MITWPU. Objective of this project was to design, manufacture and test Wheel Assembly of ACC 20C (2020 Vehicle)

2020 Vehicle Design Goals

Priority

Reliability

The most important goal was to build a car that would clear all scrutiny tests and successfully complete all dynamic events.

Drivability

Focus was given on

good driver

ergonomics and an

interface that would

allow the driver to

respond quickly to the

feedback received

from car.

Simplicity

With emphasis on

simple design and

part count reduction,

the team aimed at

maximizing time for

testing various

systems and driver

training.

Manufacturability

Designing components

to aid accurate, simple

and fast manufacturing

to maximize testing

time and ensure easily

replaceable parts.

Weight

A target weight of

175kg was set, a 15kg

reduction from the

previous iteration.

Design Concepts

Tool Used: Solidworks 2018

Bearing casing welded to upright

Bearing damaged due to welding contraction

Initial Concept for Wheel Assembly

In the first concept, Mild Steel casing was welded with Mild Steel sheets. But due to welding contraction in casing, the bearings in casing got damaged.

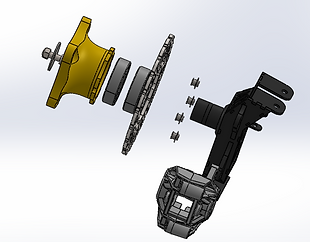

Final Concept for Wheel Assembly

To counter this in next iteration of wheel assembly, a C45 axle was welded to Mild Steel sheets. Bearings were put on this axle which were then press fitted into the Spindle.

Material Selection

Material for Spindle and Upright manufacturing was chosen based on vehicle design goals.

Preferred

Unpreferred

Mild Steel

Aluminium T6 -6061

Aluminium T6 -2014

Reliability

High Fatigue life of components

Manufacturability

Easy to manufacture

Weight

Lower un sprung mass of vehicle

Material Selection Matrix for Spindle and Upright.

The results from selection matrix results led to the choice of Mild Steel for manufacturing Uprights and Aluminum T6 2014 for manufacturing the Spindle.

The brakes team decided on Rotor Material depending on the friction coefficient between the Brake pads and the Rotor.

Rim, Tyre, and Calipers were OEM components. These were reused from the previous vehicle due to budget constraints.

Analysis

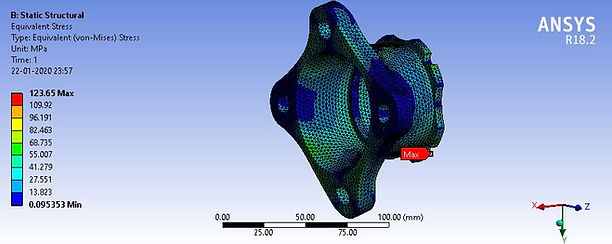

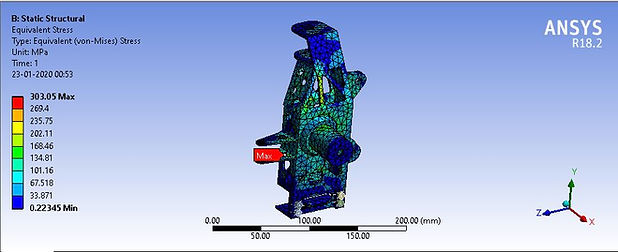

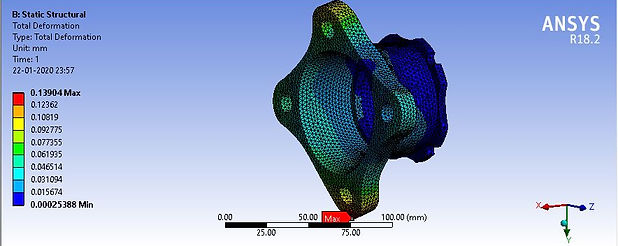

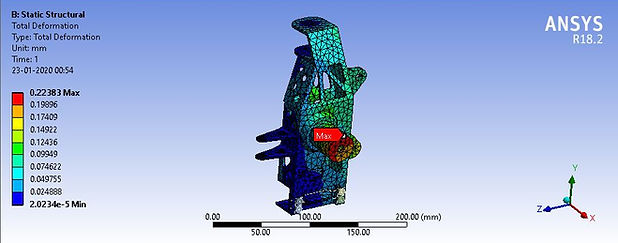

Tool Used: Ansys R18.2

As per the DAQ data from last year's vehicle, the vehicle experiences loads of 1.4g Braking, 1.2g Cornering, and 2g Bump. So the upright and spindle were analyzed for these load cases.

Stress plots for Spindle and Upright

Deformation plots for Spindle and Upright

Manufacturing

The spindles were manufactured from Aluminum T6-2014 billets through precision machining.

The uprights were manufactured by welding together laser-cut Mild Steel components.

Upright Laser Cuts

Mild Steel Welded Upright Challenges

While welding, the geometry of Upright should not change due to welding contraction as it would alter all the suspension parameters of the vehicle.

Solution

Fixtures were used to ensure the axle angle did not change due to welding contraction.

Clamps were used to constrain the motion of Mild Steel Laser cuts due to welding contraction.

Manufacturing MS Uprights

Final Assembly